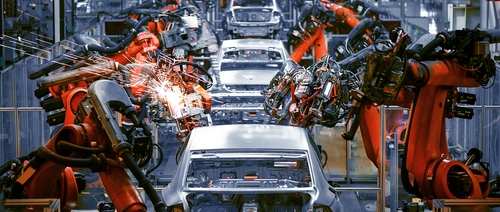

In the best of times, keeping production flowing is challenging. Those working to ensure the right parts are in the right place at the right time are used to novel surprises causing disruptions, but none of us has seen a bigger surprise than the level of impact from the worldwide COVID-19 pandemic. Most manufacturers will be looking for ways to overcome the challenges in front of them for the remainder of 2020 as they work to recover from this worldwide shock—what will differentiate those that just survive from those that bounce back even stronger? As companies work to recover, the right processes and tools will make the difference in which bounce back quickly—leveraging the StrataFlows modules to help coordinate, automate, and communicate part flow has helped others overcome challenges in the past, keep reading to learn how.

At StrataFlows we have a history of helping companies of different sizes deal with surprises. The founders of StrataFlows developed their experience with resilient systems helping IT departments deal with or avoid outages in their computing systems. They were actively doing that when called by John Deere and asked if they could apply similar tools and expertise to systematize the impact Deere was facing on their production lines at their Harvester plant in Moline, Illinois. The plant was under considerable stress due to a compounded combination of external factors at the time, not unlike the stress the virus pandemic created.

The production line was all too frequently shutting down due to material flow issues. Many of these issues stemmed from challenges in systematically handling and communicating potential part shortages. That is, in handling “hot part” requests as they refer to them. StrataFlows turned on their platform for both the plant and the warehouses the plant pulls parts from and then configured and tuned the existing StrataFlows processes to their needs.

Within a couple of weeks, production was running much more smoothly, and many fewer runs were being made between the plant and the warehouse for hot parts. StrataFlows has since gone on to implement more than 12 processes related to material flow for Deere. We can deliver these same processes for your organization quickly, or work with your team as we have with Deere and automate any process that requires automation.

StrataFlows has since repeated this a number of times at different plants, quickly helping resolve chaotic part flow through the application of their various process automation modules.

Please reach out to one of our process experts to learn how we can help improve your material flow related processes—including issues throughout the supply chain.